Industry 4.0 raises the bar for SK Food Group’s national manufacturing operations; UberData Networks engineers a Tellabs Optical LAN network that cuts costs and balances both machine and human connectivity demands.

SK Food Group mirrors what many manufacturers, distribution facilities, industrial sites and smart warehouses across the US are doing to leverage the fourth industrial revolution (Industry 4.0) by automating traditional manufacturing and industrial practices. Industrial Internet of Things (IIoT), Machine-to-Machine (M2M) learning and smart devices are used for system controls, asset tracking, predictive maintenance, autonomous robots, data collection, Artificial Intelligence, and predictive analytics. Approximately 20-30 billion machines will be connected to the Internet by the end of 2020. While these massive changes boost efficiency, productivity, and safety, they are also presenting significant challenges to network connectivity and security.

SK Food Group mirrors what many manufacturers, distribution facilities, industrial sites and smart warehouses across the US are doing to leverage the fourth industrial revolution (Industry 4.0) by automating traditional manufacturing and industrial practices. Industrial Internet of Things (IIoT), Machine-to-Machine (M2M) learning and smart devices are used for system controls, asset tracking, predictive maintenance, autonomous robots, data collection, Artificial Intelligence, and predictive analytics. Approximately 20-30 billion machines will be connected to the Internet by the end of 2020. While these massive changes boost efficiency, productivity, and safety, they are also presenting significant challenges to network connectivity and security.

SK Food Group’s Director of IT, Melissa Stone, realized the need for innovative networking solutions at their facilities across the US as they sought to achieve their smart manufacturing goals. She looked to network integrator UberData Networks to design and implement Tellabs® Passive Optical LAN at their Phoenix, Arizona manufacturing plant with resounding success.

Tellabs’ Optical LAN solution is a passive point-to-multipoint fiber-based infrastructure for in-building and property-wide network connectivity. Compared to traditional active point-to-point switched design, Optical LAN provides simplicity, centralized management efficiencies, greater network uptime and unparalleled scalability, resulting in both lower initial deployment costs and reduced ongoing operational costs.

Passive Optical LAN positively impacts IT resources, staffing and budgets. For SK Food Group, these Optical LAN benefits directly contributed to:

- 50% lower day-1 capital costs

- 70% reduction in ongoing operational costs

- Elimination of future network refresh costs

50% lower Day-1 capital costs

If SK Food Group were to have approached their transition to Industry 4.0 using a traditional network, it would have required dedicating significant resources and capital. Instead, the Passive Optical LAN architecture resulted in lower capital expenditures through a simplified network design built with flexible cabling options.

Simplified Network Design – Optical LAN boasts a passive fiber connectivity range of 12 miles, allowing SK Food Group to eliminate network closets and cabinets. Elimination of closets directly results in faster Moves, Adds and Changes (MACs) and far less planning, business disruption and costs associated with those events.

Simplified Network Design – Optical LAN boasts a passive fiber connectivity range of 12 miles, allowing SK Food Group to eliminate network closets and cabinets. Elimination of closets directly results in faster Moves, Adds and Changes (MACs) and far less planning, business disruption and costs associated with those events.

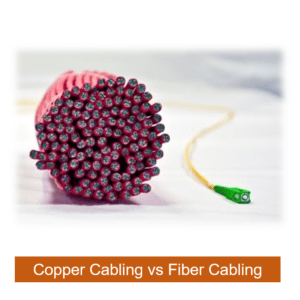

Optical LAN supports greater physical connectivity density in the main data center, across the risers and horizontal pathway cabling and at the endpoints. Current singlemode fiber (SMF) cabling bandwidth is nearly limitless. OLAN designs often have a single fiber cable transmitting 128 gigabit Ethernet connections, compared to traditional copper CATx cable serving only one gigabit Ethernet. The Optical LAN equipment in the main data center can support 2,000 to 7,000 Gigabit Ethernet connections while occupying less than one 7’ rack, including powering and fiber management.

Flexible Options for All Cabling – Fiber cabling is significantly less expensive to purchase and install compared to copper cabling – approximately 66% less. Optical LAN provides the flexible layout of either a closet-based ONT design where the last 300’ of copper cabling is leveraged, or a deep fiber design where fiber is pushed as close to the connected device as possible. That means when designing the ideal network, both copper cabling and singlemode fiber infrastructure can be used in an economical manner.

Flexible Options for All Cabling – Fiber cabling is significantly less expensive to purchase and install compared to copper cabling – approximately 66% less. Optical LAN provides the flexible layout of either a closet-based ONT design where the last 300’ of copper cabling is leveraged, or a deep fiber design where fiber is pushed as close to the connected device as possible. That means when designing the ideal network, both copper cabling and singlemode fiber infrastructure can be used in an economical manner.

Additionally, armored fiber can be utilized to reduce or even eliminate the need for conduit. This is another flexible design consideration of OLAN that can greatly reduce the overall solution cost.

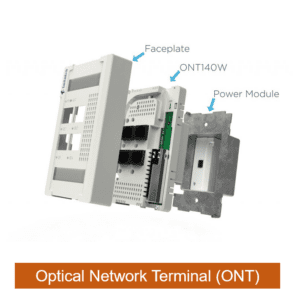

Unlike traditional networking gear, Optical LAN equipment can tolerate wide swings in temperature found in manufacturing facilities. This provided SK Food Group with great flexibility in the mounting locations for the small endpoint boxes called Optical Network Terminals (ONT). In non-climate-controlled areas, ONTs can operate within -40°F to 140°F.

Unlike traditional networking gear, Optical LAN equipment can tolerate wide swings in temperature found in manufacturing facilities. This provided SK Food Group with great flexibility in the mounting locations for the small endpoint boxes called Optical Network Terminals (ONT). In non-climate-controlled areas, ONTs can operate within -40°F to 140°F.

Industry 4.0 components can generate electromagnetic (EMI) or radio frequency (RFI), a stumbling block in traditional networks that requires shielded Cat-6A cabling. However, Optical LAN is not susceptible to EMI or RFI, so the fiber cabling can be run in a more direct route with no concern for interference.

Furthermore, Tellabs Optical LAN has the ability to utilize multimode fiber cabling. Many manufacturing plants have legacy multimode cabling in place. Network renovations with Tellabs Optical LAN can reduce costs further by leveraging existing multimode cabling infrastructure. The Tellabs OLAN solution uniquely allows PON technology to operate on both singlemode and OM1/2/3/4 multimode fiber. For example, SK Food Group saved $10,000 by taking advantage of this PON over multimode cabling solution at their Tupelo, MS facility renovation project.

Furthermore, Tellabs Optical LAN has the ability to utilize multimode fiber cabling. Many manufacturing plants have legacy multimode cabling in place. Network renovations with Tellabs Optical LAN can reduce costs further by leveraging existing multimode cabling infrastructure. The Tellabs OLAN solution uniquely allows PON technology to operate on both singlemode and OM1/2/3/4 multimode fiber. For example, SK Food Group saved $10,000 by taking advantage of this PON over multimode cabling solution at their Tupelo, MS facility renovation project.

In summary, SMF cabling is smaller, lighter and stronger, having better bend radius, higher bandwidth capacity, and longer reach. SMF has no electromagnetic interference impact, faster connector solutions, longer life and non-corrosive, making it more secure and less expensive.

“We gained a 41% lower equipment savings at our 220,000 sf Phoenix facility with an Optical LAN design compared to a traditional copper-based network design,” said Melissa Stone, SK Food Group IT Director. “At that same Phoenix property, we identified a 53% savings for Optical LAN that can be attributed to lower infrastructure costs.”

70% reduction in ongoing operational costs

While Industry 4.0 can rely heavily on M2M automation, humans are still tasked with managing those machines. The reduction of human staff can save money, but it also elevates the physical and mental hardships for those employees responsible for safe and productive daily operations. Picture a traditional network design: distributed intelligence with many highly complex network switches spread out across a manufacturing facility due to strict connectivity distance limitations. This legacy network architecture is poorly suited to handle the connectivity demands of Industry 4.0, therefore increasing both operational costs and stress on the IT staff.

Operational Efficiencies – Optical LAN is founded on the premise of centralized intelligence and management, enabling lower operational and maintenance costs while reducing the opportunity for human error. Think of the technology as one common switch, with virtual “Ethernet extended” connectivity over a passive network (passive = no power, no maintenance and highly reliable). End-to-end network management is now one single management console that orchestrates all endpoints, including the powered devices. This is all possible because of Optical LAN’s inherent Software Defined Networking (SDN) roots that promote the use of global profiles for consistent error-free provisioning. For SK Food Group, this equated to lower operational costs via fewer staff, less human touch, easier training, and no need to contract more expensive network engineers.

Operational Efficiencies – Optical LAN is founded on the premise of centralized intelligence and management, enabling lower operational and maintenance costs while reducing the opportunity for human error. Think of the technology as one common switch, with virtual “Ethernet extended” connectivity over a passive network (passive = no power, no maintenance and highly reliable). End-to-end network management is now one single management console that orchestrates all endpoints, including the powered devices. This is all possible because of Optical LAN’s inherent Software Defined Networking (SDN) roots that promote the use of global profiles for consistent error-free provisioning. For SK Food Group, this equated to lower operational costs via fewer staff, less human touch, easier training, and no need to contract more expensive network engineers.

In addition, reducing human touch lowers human error, directly impacts business continuity and security. Many studies have shown that human error is the greatest cause for network outages and security breaches – both of which can cripple a manufacturing business.

Faster Moves, Adds, and Changes – Operations for manufacturers is constantly growing and changing. Their underlying networks need to be flexible and scalable to support economical Moves, Adds and Changes (MACs). This can be exacerbated by a sprawling footprint, high ceilings and harsh conditions. With a traditional network architecture, adding connectivity ports may require moving or adding a cabinet, adding a new Ethernet and/or running copper cabling all the way back to the main closet or to a cabinet 35-40 feet off the ground. This is considerably time consuming, complex and expensive. SK Food Group has experienced strong growth over the past 6 years, increasing output from 4 million to 20 million units per week. Thus, these MAC demands were very burdensome in SK Food Group’s old network scenario.

Faster Moves, Adds, and Changes – Operations for manufacturers is constantly growing and changing. Their underlying networks need to be flexible and scalable to support economical Moves, Adds and Changes (MACs). This can be exacerbated by a sprawling footprint, high ceilings and harsh conditions. With a traditional network architecture, adding connectivity ports may require moving or adding a cabinet, adding a new Ethernet and/or running copper cabling all the way back to the main closet or to a cabinet 35-40 feet off the ground. This is considerably time consuming, complex and expensive. SK Food Group has experienced strong growth over the past 6 years, increasing output from 4 million to 20 million units per week. Thus, these MAC demands were very burdensome in SK Food Group’s old network scenario.

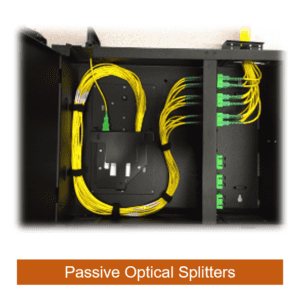

For SK Food Group, the process of MAC work is reduced from months to days with an Optical LAN. In particular, an ONT or splitter can be located nearby to make a fast connection. The fiber pathway can be smaller, shorter, and impose no EMI or RFI concerns. In summary, Optical LAN network changes are simple, fast and inexpensive.

The elimination of network closets and cabinets is an even bigger benefit for SK Food Group, since in a traditional network design, it is common practice to mount the cabinets to the ceiling 35-40 feet above the floor. Those ceiling cabinets are only accessible via fork or scissor lifts which introduces time consuming maintenance, troubleshooting and safety issues (imagine training IT staff on fork/scissor lift use and safety). Eliminating these cabinets not only reduces capital and operational costs; it is safer for employees and can improve OSHA reporting for manufacturers.

The elimination of network closets and cabinets is an even bigger benefit for SK Food Group, since in a traditional network design, it is common practice to mount the cabinets to the ceiling 35-40 feet above the floor. Those ceiling cabinets are only accessible via fork or scissor lifts which introduces time consuming maintenance, troubleshooting and safety issues (imagine training IT staff on fork/scissor lift use and safety). Eliminating these cabinets not only reduces capital and operational costs; it is safer for employees and can improve OSHA reporting for manufacturers.

Lower Annual Support Costs – Optical LAN can lower annual support costs compared to what traditional switch manufacturers charge. These types of year-over-year operational expense savings for SK Food Group are significant. For example, SK Food Group cut their annual support costs in half as they transitioned from a major switch vendor 24x7x365 annual support to Tellabs 24x7x365 annual support (including advanced equipment replacement).

“As a result of deploying Passive Optical LAN technology at our facilities, we’ve gained an approximate 70% operational savings due to reduction in IT engineering, centralized management, and the ability to perform faster MACs,” stated Stone. “We have also calculated a 52% savings in annual support costs.”

Elimination of future network refresh costs

Historically, manufacturer networks have been in a constant state of flux in three main areas First, the growth of connected endpoints, then the increased bandwidth demands and finally, ongoing wholesale technology changes. Through the years this has forced SK Food Group into a repetitive cycle of rip-and-replace upgrades for both network electronics and cable infrastructure. These IT equipment (every 3-5 years) and network infrastructure (every 5-7 years) refreshes come with big price tags and are very disruptive to manufacturing operations. With Optical LAN in place, SK Food Group has the industry’s best possible investment protection.

Unparalleled Scalability – The fiber-based infrastructure is for all practicality future-proof, with no known connectivity, bandwidth nor technology limitations. And once again, the Optical LAN design offers flexible future scalability at the headend chassis Optical Line Terminal (OLT) PON port, at the optical splitter, and the ONT. All of this provides SK Food Group with the peace of mind that rip-and-replace events are in the past.

Unparalleled Scalability – The fiber-based infrastructure is for all practicality future-proof, with no known connectivity, bandwidth nor technology limitations. And once again, the Optical LAN design offers flexible future scalability at the headend chassis Optical Line Terminal (OLT) PON port, at the optical splitter, and the ONT. All of this provides SK Food Group with the peace of mind that rip-and-replace events are in the past.

Technology Independence – With no known bandwidth limitation for fiber, SK Food Group can freely migrate to new technologies gracefully and economically. The Optical LAN is based on wave-division multiplexing technology enabling today’s infrastructure can support of 2.5G G-PON and 10G XGS-PON with no wavelength conflicts. In the future, SK Food Group can upgrade their network on a per port basis to 10G, 40G and 100G PON speeds, then economically place 10G, 40G and 100G PON ONTs only where that increased capacity is truly required.

“Since Optical LAN supports the migration to 10G, 25G, 40G, and 100G over the same fiber infrastructure with minimal impact to manufacturing operations, we are in a sense future-proofing our network, and that was very important to SK Food Group,” commented Stone.

OLAN flexibility delivers SK Food Group CapEx and OpEx savings

SK Food Group’s Phoenix manufacturing plant is meeting the demands of Industry 4.0 with Tellabs Optical LAN. The OLAN architecture in a manufacturing environment has proven to be more flexible in design, and lower in cost, all while balancing both M2M and human connectivity needs. Under the skilled leadership of UberData Networks, SK Food Group has successfully implemented Optical LAN at six additional facilities in the across the USA.

SK Food Group’s Phoenix manufacturing plant is meeting the demands of Industry 4.0 with Tellabs Optical LAN. The OLAN architecture in a manufacturing environment has proven to be more flexible in design, and lower in cost, all while balancing both M2M and human connectivity needs. Under the skilled leadership of UberData Networks, SK Food Group has successfully implemented Optical LAN at six additional facilities in the across the USA.

To learn more details about the SK Food Group’s installation of the Tellabs Optical LAN, designed by UberData Networks, we invite you to watch this on-demand webcast replay on the topic.

***

about SK Food Group

SK Food Group is a custom food manufacturing company serving customers across North America. From product creation to flawless execution and assembly, we’re a hands-on partner, every step of the way. We are the leading producer of handcrafted sandwiches, wraps, protein snacks, flatbreads, burgers and more. It’s our privilege to make delicious products for a wide range of customers including Fortune 500 companies, QSRs, airlines, retailers, convenience stores, as well as neighborhood cafés. For more information, please visit www.skfoodgroup.com/.

about UberData Networks

UberData Networks is a full-service network system integrator for customized Passive Optical LAN (POL) solutions, with over 25 years’ experience designing passive optical networks (PON). UberData Networks offers turnkey Passive Optical LAN network solutions integrating the latest Wi-Fi wireless, Distributed Antenna System (DAS), IP Security, Building Automation, and IIoT smart technologies into enterprise networks. UberData Networks’ services and extended partner network ensures the client’s technology needs are surpassed beyond today’s expectations. For more information, please visit www.uberdatanetworks.com/.

about Tellabs

Tellabs is leading the future of networking with access solutions for today, poised to deliver modern high-performance solutions for the future. Fast and secure access has never been in more demand for enterprise and government connectivity. Tellabs’ sole focus is to deliver simple, secure, scalable and stable access to optimize network performance. Tellabs has delivered carrier-class access solutions to service providers for more than two decades. We are now expanding that leadership by defining the future of enterprise networking that connects the campus, buildings and inspires people. For more information, please visit tellabs.com/.